Exploring the Benefits of One Off CNC Machining for Custom Projects and Prototypes

One off CNC machining has emerged as a revolutionary technique within the manufacturing sector, particularly for custom projects and prototypes. According to a report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2026, fueled by the increasing demand for personalized manufacturing solutions. This approach allows engineers and designers to create unique components that meet specific client requirements with a high degree of precision and efficiency. Notably, the flexibility of one off CNC machining enables rapid prototyping, reducing the time from concept to production by up to 50%, as highlighted by a study from the National Institute of Standards and Technology. As industries continuously seek innovative ways to streamline workflows and enhance product quality, one off CNC machining presents a compelling solution that combines versatility, cost-effectiveness, and reduced lead times, making it an indispensable tool for modern manufacturers and innovators.

Understanding One Off CNC Machining and Its Applications in Prototyping

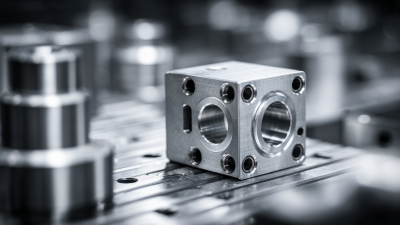

One off CNC machining plays a crucial role in custom projects and prototyping, providing a tailored approach to manufacturing unique components. This method allows designers and engineers to create complex geometries using advanced digital fabrication technologies that remain cost-effective. With innovations in adaptive robotic manufacturing and machine learning, the landscape of CNC machining has evolved, making it a preferred choice for prototyping diverse applications.

Tips for leveraging one off CNC machining include fully understanding your project requirements before beginning manufacturing. This ensures you can benefit from the precise customization available. Additionally, staying informed about advancements in prototyping technologies can further enhance your project outcomes—taking advantage of rapid prototyping techniques, for instance, may accelerate the design process significantly.

Furthermore, engaging with companies that specialize in advanced CNC machining capabilities can offer insights into optimizing your project designs. Networking with professionals in the field can lead to discovering efficient ways to integrate off-the-shelf components into your custom projects, ultimately saving time and resources while pushing the boundaries of innovation.

Key Advantages of One Off CNC Machining for Custom Projects

One off CNC machining offers a multitude of benefits for custom projects, particularly in swiftly evolving industries. With the flexibility to produce unique parts and prototypes, businesses can capitalize on market trends without the overhead of large-scale production setups. According to recent insights, this approach is increasingly in demand, with 26 profitable CNC projects identified for 2025, signifying a robust opportunity for innovation and profitability. Custom CNC machining allows for rapid iterations and refinements, essential in meeting consumer expectations in sectors such as automotive and consumer goods.

Moreover, the precision afforded by CNC technology is integral to customizing components that meet specific design requirements. For example, companies that have expanded their custom manufacturing services are leveraging advancements in CNC machining to provide tailored solutions at scale. This capability is invaluable for industries requiring high-quality, low-volume production, as businesses can reduce lead times and enhance the quality of their prototypes. As the manufacturing landscape evolves, incorporating one off CNC machining not only fosters creative engineering but also aligns with the growing trend of personalized products, making it an essential strategy for companies aiming to stay ahead in a competitive market.

Exploring the Benefits of One Off CNC Machining for Custom Projects and Prototypes

| Advantage | Description | Example Application |

|---|---|---|

| Customization | Ability to create unique components tailored to specific needs. | Custom brackets for machinery. |

| Rapid Prototyping | Quick turnaround on prototype designs for testing and validation. | Initial prototypes for product testing. |

| Cost-Effectiveness | Reduced costs for small production runs; no need for mass production. | Small batch parts for niche markets. |

| Precision Engineering | High precision and accuracy in manufacturing components. | Components requiring tight tolerances in aerospace. |

| Material Variety | Ability to work with a wide range of materials, including metals and plastics. | Custom housings made from resistant materials. |

| Design Flexibility | Adaptable designs allow for modifications even during production stages. | Evolving design concepts for consumer electronics. |

Step-by-Step Process of Creating Custom Parts with CNC Machining

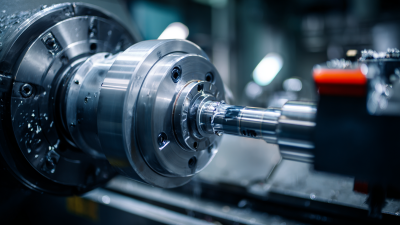

CNC machining has revolutionized the way custom parts and prototypes are produced, offering precision and efficiency that traditional methods struggle to match. The step-by-step process begins with digital modeling, where CAD software is utilized to create a detailed 3D representation of the desired part. According to a recent report from TechNavio, the global CNC machining market is projected to grow by 5.4% annually, underscoring the increasing demand for bespoke manufacturing solutions.

After designing the model, the next phase involves selecting the appropriate material. Industries today often prefer lightweight metals, plastics, and other advanced composites due to their robust properties. Once the material is chosen, CNC machining centers cut the raw material according to the digital blueprint. A 2021 study by Grand View Research indicated that around 70% of companies are now investing in CNC technologies due to their capability to reduce time and costs while maintaining high quality in production. Finally, the parts undergo quality checks and finishing processes, ensuring they meet the exact specifications before being delivered to clients, thus highlighting the efficiency and reliability of one-off CNC machining in custom projects.

Choosing the Right Materials for One Off CNC Machining Projects

When it comes to one-off CNC machining projects, selecting the right materials is crucial for achieving the desired results. According to a report by the National Institute of Standards and Technology (NIST), material choice can significantly impact the dimensional accuracy, surface finish, and overall performance of custom machined components. Commonly used materials such as aluminum, stainless steel, and plastics can each serve different purposes depending on the application. For instance, aluminum is favored for its lightweight properties and excellent machinability, making it suitable for prototypes that require precision and quick turnarounds.

Furthermore, the capabilities of CNC machines allow for a diverse range of materials, including advanced composites and specialty alloys. A study by Market Research Future indicates that the global CNC machining market is expected to grow by 7% annually, driven in part by advancements in material technology. Choosing materials that are compatible with these advanced machining processes can further enhance the outcome of custom projects. By understanding the specific properties of various materials and how they interact with CNC machining techniques, manufacturers can optimize their prototypes for functionality, durability, and cost-effectiveness.

Common Challenges in One Off CNC Machining and How to Overcome Them

One-off CNC machining presents a myriad of benefits for custom projects and prototypes, yet it comes with its own set of challenges. One of the most common issues faced is the need for precise post-processing. Post processors are essential as they translate the CNC program into machine language, enabling accurate tool movements and ensuring that the final product matches design specifications. According to industry reports, proper use of post processors can reduce machining errors by up to 30%, highlighting their importance in achieving desired outcomes.

Another challenge in one-off CNC machining is material selection, particularly when creating prototypes that require specific properties for testing. Many manufacturers often underestimate the impact of material choice on the machining process. A recent survey indicated that up to 40% of prototype failures are attributed to inadequate material selection. To overcome this challenge, it's crucial to engage with material specialists early in the project to ensure compatibility and optimal performance of chosen materials. Moreover, ongoing advancements in CNC technology are expanding the range of materials that can be efficiently machined, providing more options for prototyping and reducing the likelihood of issues during production.

Related Posts

-

Trustworthy Quality in Best Low Volume CNC Machining from China for Global Markets

-

Navigating the Future: How Best Rapid CNC Machining Will Shape Industry 2025 Trends

-

Unveiling the Key Technical Specifications of Best Carbon Fiber CNC Machines

-

Exploring Innovative Alternatives to Best Milling Machine CNC for Global Manufacturers

-

How to Achieve Fast Precision with Best Quick Turn Machining Techniques

-

5 Secrets to Finding the Best Quick Turn CNC Machining Services