Exploring Innovative Alternatives to Best Milling Machine CNC for Global Manufacturers

As global manufacturing continues to evolve, the search for innovative alternatives to traditional milling machine CNC technology has become increasingly critical. Recent reports indicate that the CNC machining market is projected to reach $112 billion by 2025, driven by advancements in automation and demand for precision manufacturing. However, traditional milling machine CNC systems face challenges such as high operational costs, maintenance issues, and limitations in adaptability to varying production needs.

Consequently, manufacturers are exploring alternative solutions that promise enhanced efficiency, lower overheads, and greater flexibility in production processes. This blog will delve into the emerging technologies and methodologies that serve as viable substitutes for conventional milling machines, highlighting their potential to reshape the manufacturing landscape in a rapidly changing industry.

Innovative CNC Milling Solutions Driving Chinese Manufacturing Success

China's rapid advancements in manufacturing technology are reshaping the global landscape, particularly in CNC milling solutions. The country's innovative capabilities are surging, driven by its universities and domestic enterprises that are increasingly embracing digital manufacturing and automation. This transformation is evident in the rise of services that cater to low-volume production and rapid prototyping, facilitating the swift development of complex components with precision.

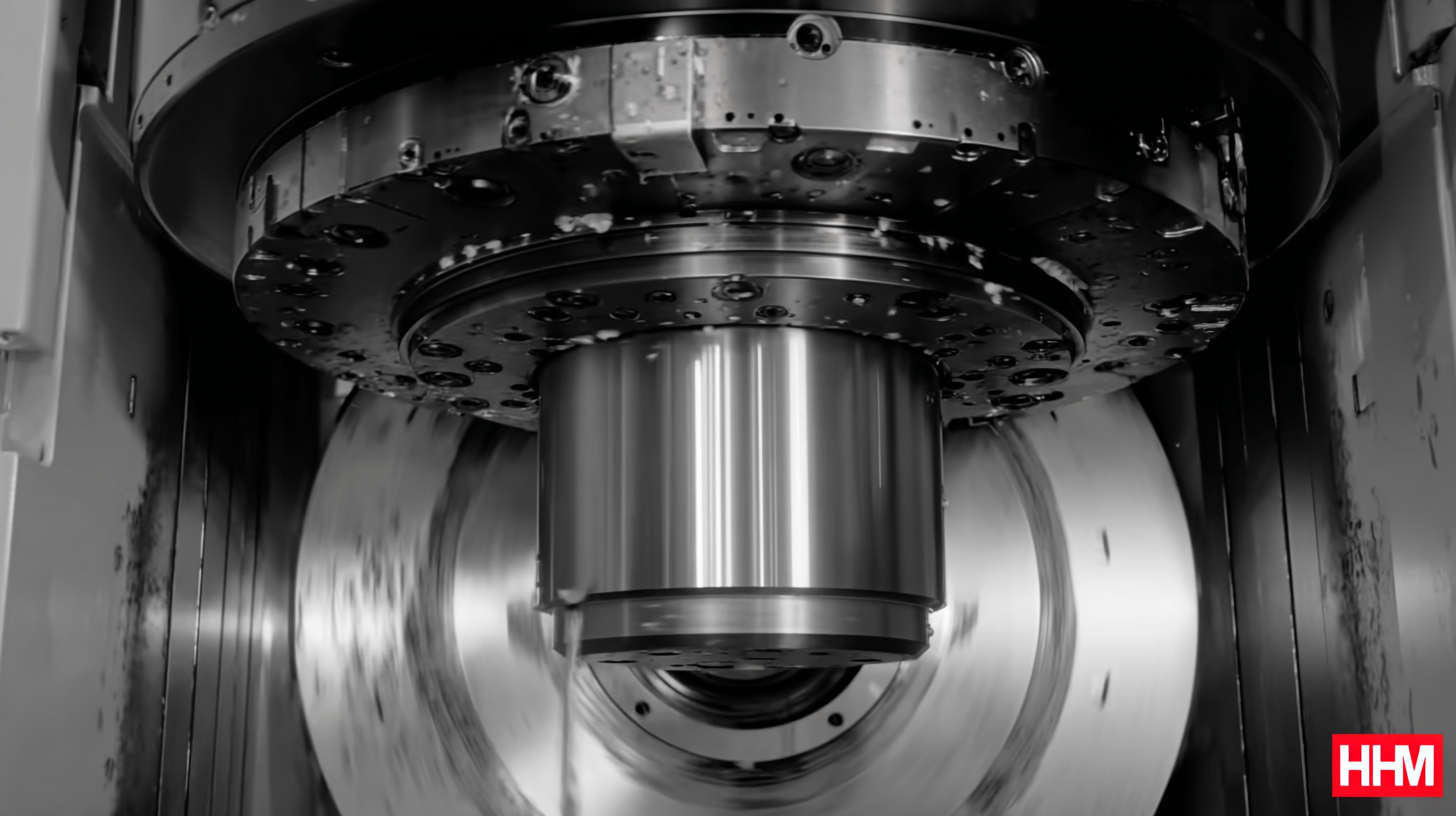

Moreover, the growth of specialized CNC solutions is particularly noteworthy. New technologies are enabling manufacturers to produce intricate robotic parts from premium materials, such as stainless steel and titanium, which are essential for the evolving demands of modern industries. As a result, Chinese manufacturers are not only meeting local needs but are also positioning themselves competitively in the global market, showcasing their capacity for innovation in sectors like robotics and advanced machining. The interplay of these innovative CNC milling solutions is crucial for ensuring sustained manufacturing success in China.

Exploring Innovative Alternatives to Best Milling Machine CNC for Global Manufacturers

| CNC Milling Solution | Maximum Spindle Speed (RPM) | Work Table Size (mm) | Accuracy (μm) | Main Motor Power (kW) | Operating System |

|---|---|---|---|---|---|

| Compact CNC Mill A | 12000 | 800 x 500 | 5 | 7.5 | Fanuc |

| Advanced CNC Mill B | 15000 | 1000 x 600 | 3 | 11 | Siemens |

| High Precision CNC Mill C | 18000 | 1200 x 800 | 2 | 15 | Mitsubishi |

Key Features of Leading CNC Milling Machines from China

As global manufacturers seek innovative alternatives to traditional CNC milling machines, the focus on key features of leading machines from China becomes increasingly relevant. With the CNC machine market projected to grow significantly, it is crucial for businesses to consider not only the specifications but also the technological advancements that Chinese manufacturers are introducing. These innovations often include enhanced precision, faster processing speeds, and multifunctional capabilities that provide manufacturers with valuable flexibility in production processes.

China's machine tool industry, recognized as the world's largest, is making strides in innovation, driven by robust investments in technology and a strong emphasis on research and development. The remarkable fourfold increase in metalworking machinery exports to Russia signifies China's growing role in the global supply chain, especially within advanced industries. By understanding the strengths of leading CNC milling machines from China, manufacturers can better equip themselves to meet the demands of a rapidly evolving market and harness new opportunities that emerge from this innovative landscape.

Comparison of Key Features in CNC Milling Machines

Comparative Analysis: Chinese CNC Machines vs. Global Competitors

The global CNC machine market is poised for significant growth, with a projected market size reaching 271.6 billion USD by 2025 and an anticipated increase to 446.4 billion USD by 2033, reflecting a compound annual growth rate of 6.4%. This expansion underscores the rising demand for precision and automation in manufacturing processes across various industries.

Chinese manufacturers are making notable strides in the CNC machine sector, contributing to a domestic market size of 409 billion yuan in 2023, with a consistent annual growth rate of 5.75% from 2019 to 2023. As the industry undergoes a structural transformation, advanced manufacturing techniques are gradually overtaking traditional methods, exemplified by the increasing adoption of high-end five-axis machine tools. This category of machinery is crucial for precision machining and is indicative of China's capacity to compete on a global scale, as it ranks among the top 25 machine tool producers worldwide.

Furthermore, the precision instrument sector, characterized by a low market concentration, showcases numerous opportunities for manufacturers to innovate and expand their operational footprints. As the competitive landscape evolves, the distinction between Chinese CNC machines and their global rivals will become more pronounced, emphasizing the need for continuous improvement and adoption of cutting-edge technologies in the manufacturing arena.

The Role of Technology in Enhancing CNC Milling Efficiency

In the fast-evolving world of manufacturing, the role of technology in enhancing CNC milling efficiency cannot be overstated. According to a report from MarketsandMarkets, the global CNC machine market is projected to grow from $76.12 billion in 2021 to $117.70 billion by 2026, reflecting a compound annual growth rate (CAGR) of 9.0%. This growth is primarily driven by advancements in automation, artificial intelligence, and IoT integration, which are transforming traditional CNC systems into smart, interconnected units that optimize performance and reduce operational costs.

Recent developments in adaptive machining technologies, such as real-time toolpath adjustments and adaptive feed rate management, allow manufacturers to enhance operational efficiency significantly. A study conducted by the American Machinist reveals that such innovations can lead to a remarkable 30-40% reduction in machining time, while simultaneously improving the surface finish quality of the produced components. These technologies ensure that CNC milling machines not only meet precision requirements but also enhance productivity and sustainability in the manufacturing process.

Future Trends in CNC Milling: Shaping the Manufacturing Landscape

The landscape of CNC milling continues to evolve with revolutionary trends that are set to redefine manufacturing practices globally. According to a report by Markets and Markets, the global CNC milling machine market is projected to reach $23.11 billion by 2025, growing at a CAGR of 6.9%. This growth reflects not only an increasing demand for precision and efficiency but also a shift towards innovative technologies that enhance productivity and reduce operational costs.

Key future trends include the integration of Industry 4.0 concepts, whereby manufacturers are adopting smart milling machines equipped with IoT capabilities. This transition allows for real-time monitoring and data analytics, providing manufacturers with unprecedented insights into their operations. Additionally, advancements in materials and tooling—such as the development of ceramic and composite materials—are enabling CNC machines to achieve higher performance levels, catering to a variety of industries from aerospace to automotive.

Furthermore, the push for sustainability is influencing the CNC milling sector, with manufacturers looking for ways to minimize waste and energy consumption. A report from the National Institute of Standards and Technology (NIST) indicates that adopting energy-efficient practices in machining can reduce operational costs by up to 30%. As global manufacturers explore these innovative alternatives, the impact on productivity and environmental sustainability is set to create a significant ripple effect across the industry.