Comparing the Top Innovations in Prototype Machining Techniques

In the rapidly evolving world of manufacturing, the significance of prototype machining has surged to unprecedented heights. As industries strive for innovation and efficiency, various machining techniques have emerged, each designed to enhance the prototyping process. This blog aims to delve into the realm of prototype machining by comparing the top innovations in the field. We will explore the latest technologies that streamline production, improve precision, and reduce turnaround times, ensuring that designers and engineers can bring their visions to fruition more effectively. By examining these cutting-edge techniques, we will highlight how they contribute to the overall advancement of product development and manufacturing, empowering businesses to stay competitive in a dynamic market. Join us as we explore the essentials of modern prototype machining and uncover best practices that can elevate your production capabilities.

Revolutionizing Prototype Machining: The Rise of Additive Manufacturing Techniques in 2023

The rise of additive manufacturing techniques in 2023 has fundamentally transformed the landscape of prototype machining, particularly in the aerospace sector. This innovative approach leverages the unique advantages of composite materials, marrying their impressive strength-to-weight ratio with the design flexibility inherent in 3D printing. Such an integration allows aerospace engineers to create more efficient and environmentally friendly aircraft by improving fuel efficiency and reducing emissions.

With this advanced technology, prototype machining is no longer limited by traditional manufacturing constraints. Designers can now experiment with complex geometries that were previously deemed impractical, enabling the production of lightweight components that enhance performance. As the industry continues to embrace these innovations, the potential for breakthroughs in both design and functionality is unprecedented. Additive manufacturing techniques are not just revolutionizing how prototypes are created; they are also setting the stage for a more sustainable future in aerospace engineering.

Understanding CNC Machining Innovations: Enhancements in Precision and Cost-Effectiveness

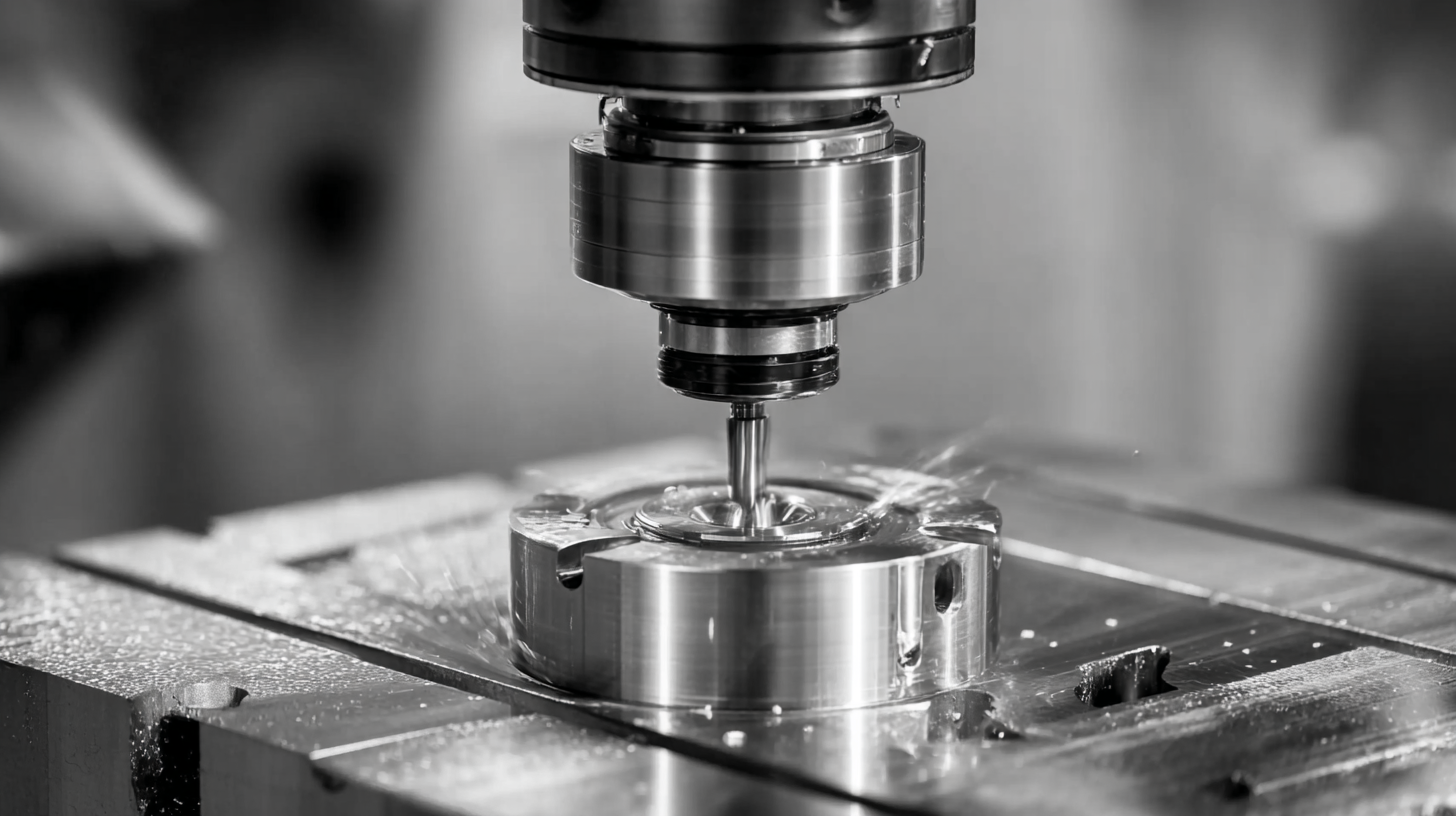

In recent years, the landscape of CNC machining has undergone significant transformations, driven by innovative techniques that enhance precision and cost-effectiveness. The integration of advanced software and automated systems has elevated traditional machining processes, allowing for tighter tolerances and greater consistency. These innovations enable manufacturers to produce complex geometries with remarkable accuracy, thereby reducing waste and ensuring that production meets the exact specifications required by modern industries.

Moreover, the emergence of hybrid machining technologies is bridging the gap between additive and subtractive manufacturing. By combining these two approaches, engineers can now create high-quality prototypes more efficiently and affordably. This trend not only shortens lead times but also minimizes material usage, significantly lowering production costs. As CNC machining continues to evolve, businesses investing in these innovative techniques are better positioned to meet the growing demands for rapid prototyping and customized solutions in an increasingly competitive market.

Exploring Hybrid Machining Methods: Combining Subtractive and Additive Technologies for Optimal Results

The evolution of prototype machining techniques has led to the emergence of hybrid machining methods, which effectively combine subtractive and additive technologies. This fusion offers a transformative approach to manufacturing, allowing for more complex geometries and enhanced precision in the production of prototypes. By integrating these two distinct methodologies, manufacturers can leverage the strengths of each to achieve optimal results in both efficiency and quality.

Subtractive machining typically involves processes like milling, turning, and drilling, where material is sequentially removed to create the desired shape. On the other hand, additive manufacturing builds parts layer by layer, which can be advantageous for producing intricate designs that are difficult to achieve through traditional means. With hybrid techniques, engineers can begin with a solid block and use subtractive methods to refine the overall shape, subsequently adding specific features using additive processes. This allows for reduced material waste and faster turnaround times, catering to the fast-paced demands of industries such as aerospace, automotive, and medical devices, where prototype development cycles can dictate overall project success.

The Impact of Automation in Prototype Machining: Increasing Production Efficiency by 30%

The integration of automation in prototype machining is revolutionizing production efficiency, with projections indicating a staggering 30% increase in output. The landscape of machining technologies is rapidly evolving, and recent studies highlight the significant investments that industrial companies are making towards robotics and automation. The McKinsey Global Industrial Robotics Survey of 2022 reported that companies are poised to allocate substantial resources into these technologies, aiming at enhancing operational efficiency and reducing turnaround times.

In the broader CNC machines market, a remarkable growth trajectory is anticipated, with projections suggesting an increase from USD 66.9 billion in 2023 to USD 170.4 billion by 2033, growing at a compound annual growth rate (CAGR) of 9.80%. This growth underscores the industry's shift towards advanced automation and AI integration. AI is not merely a buzzword but a core component that is streamlining manufacturing processes. By employing data and sophisticated algorithms, AI is enhancing precision and responsiveness, ultimately leading to smarter production systems that are better equipped to navigate the complexities of modern manufacturing challenges.

Comparing the Top Innovations in Prototype Machining Techniques

| Innovation Technique | Description | Efficiency Improvement (%) | Implementation Time (Months) | Cost (USD) |

|---|---|---|---|---|

| CNC Machining | Computerized control of machining tools | 30% | 6 | 50,000 |

| 3D Printing | Additive manufacturing for rapid prototyping | 40% | 3 | 30,000 |

| Laser Cutting | Using laser technology for cutting materials | 25% | 4 | 20,000 |

| Injection Molding | Process for producing parts by injecting materials | 35% | 5 | 100,000 |

Sustainable Practices in Prototype Machining: Reducing Waste and Energy Consumption in Manufacturing

Sustainable practices in prototype machining have emerged as a critical focus for manufacturers aiming to reduce waste and energy consumption. According to a report by the International Journal of Advanced Manufacturing Technology, roughly 30% of materials are wasted in traditional machining processes due to inefficient designs and excess cutting. By adopting advanced technologies such as additive manufacturing and computer numerical control (CNC) systems, manufacturers can significantly minimize this waste. Integrating software that emphasizes simulation and optimization can also reduce material removal and enhance the overall efficiency of the machining process.

Energy consumption in manufacturing remains a substantial concern, with machining alone accounting for approximately 25-30% of total industrial energy use. A study conducted by the U.S. Department of Energy highlights that implementing energy-efficient equipment and practices can lead to a reduction of up to 15% in energy consumption during machining operations. Manufacturers can further enhance sustainability by incorporating renewable energy sources such as solar or wind power in their facilities. By prioritizing sustainable practices in prototype machining, companies can not only improve their environmental footprint but also optimize their production processes for long-term cost savings and operational efficiency.

Comparing Innovations in Prototype Machining Techniques

This chart illustrates the advancements in various prototype machining techniques focusing on sustainable practices, highlighting their potential in reducing waste and energy consumption in manufacturing.