Trustworthy Quality in Best Low Volume CNC Machining from China for Global Markets

In recent years, the demand for low volume CNC machining has surged as industries recognize the benefits of agile manufacturing processes that cater to specific market needs. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach USD 100 billion by 2025, with a significant segment driven by the growing preference for customized solutions and rapid prototyping. This shift underscores the importance of finding trustworthy suppliers capable of delivering high-quality parts with quick turnaround times, especially within global markets. As manufacturers increasingly seek to optimize production efficiencies while maintaining stringent quality standards, low volume CNC machining has emerged as a critical strategy for companies aiming to gain a competitive edge. In this blog, we will explore the best practices in sourcing CNC machining services from China, illustrating how businesses can leverage these capabilities for superior outcomes.

Importance of CNC Machining in Global Manufacturing Markets

CNC machining plays a pivotal role in the global manufacturing landscape, driven by its ability to deliver high precision and efficiency. The global CNC controller market, valued at $3.2 billion in 2023, is projected to expand to $7.2 billion by 2033, growing at a staggering CAGR of 8.3%. This significant growth underscores the increasing reliance on CNC technology across various industries, from automotive to aerospace, for manufacturing intricate components with reduced lead times and enhanced quality.

As digital transformation continues to reshape manufacturing processes, companies are leveraging advancements like IoT and AI to optimize production strategies. The precision engineering machines market is anticipated to grow from $20.09 billion in 2025 to approximately $29.16 billion by 2034, highlighting the industry's shift towards smarter manufacturing solutions. These trends emphasize the necessity for manufacturers to adopt innovative CNC machining techniques to remain competitive in an ever-evolving market.

**Tip:** Embrace automation and digital twin technology to streamline operations and improve product quality.

**Tip:** Invest in training your workforce to effectively use advanced CNC tools, as skilled operators can greatly enhance productivity and innovation.

Trustworthy Quality in Best Low Volume CNC Machining

This chart illustrates the global demand and quality perception of low volume CNC machining services across various countries.

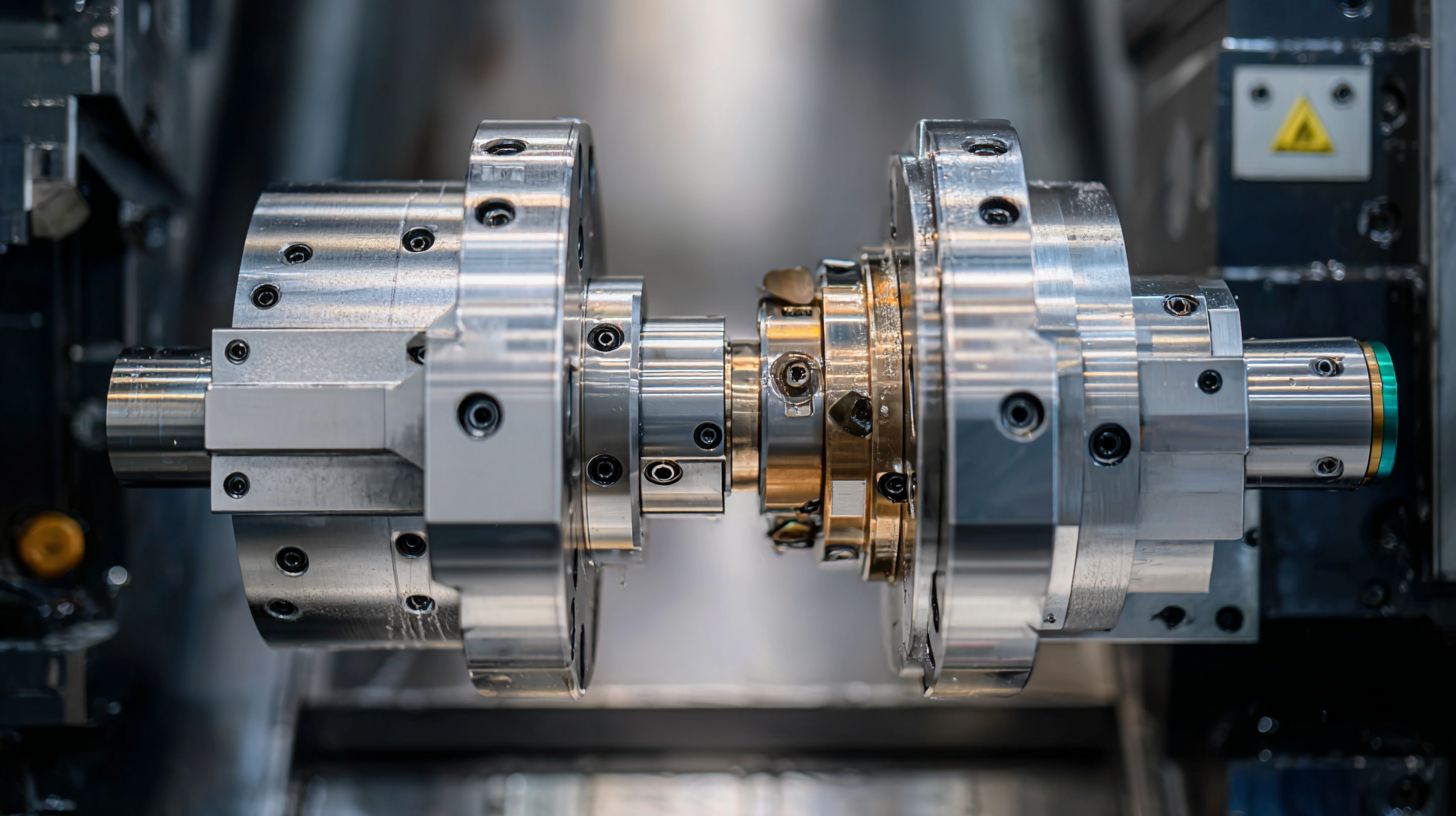

Key Factors to Consider When Choosing a CNC Machining Partner in China

When selecting a CNC machining partner in China, it’s crucial to consider several key factors that can impact the quality and reliability of your production. First, assess the partner’s certifications and quality management systems. According to the ISO 9001 standard, which many reputable CNC machining companies adhere to, a robust quality management system ensures consistent quality and process improvement. This is pivotal as it contributes directly to the finished product's performance and longevity, especially in competitive global markets.

Another essential factor is the technological capability of the facility. A report by Frost & Sullivan highlights that CNC machining companies utilizing advanced technologies such as automation and high-precision machinery can significantly reduce error rates and production times. This technological edge not only enhances the precision of the manufactured parts but also ensures timely delivery, a crucial element in today’s fast-paced business environment.

Tip: Before finalizing a partnership, request samples and conduct a thorough quality inspection. This hands-on assessment can reveal insights into the machining processes and quality control measures employed.

Tip: Ensure clear communication and establish a strong relationship with your partner. This facilitates better problem resolution and can lead to more innovative solutions tailored to your specific needs.

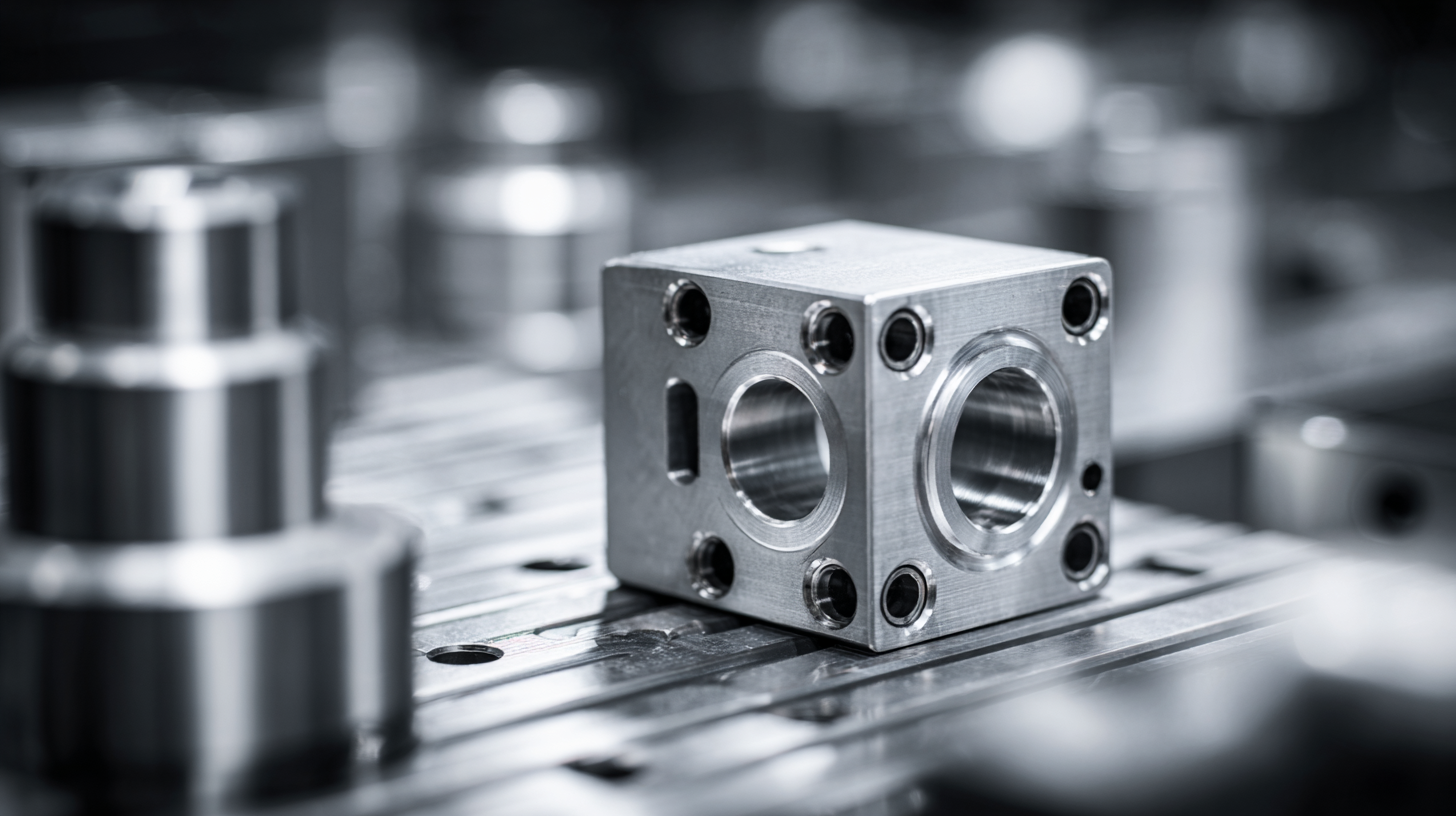

Quality Assurance Practices for Low Volume CNC Machining

Quality assurance is a critical aspect of low volume CNC machining, especially as the global CNC market is projected to experience significant growth in the coming years. With advancements in technology, the ability to maintain high-quality standards while meeting the increasing demand for precision parts is more vital than ever. Companies must implement rigorous quality control practices throughout the machining process, from initial design checks to final inspections. This ensures that every component produced not only meets customer specifications but also exceeds industry standards, particularly in high-stakes sectors like aerospace and medical devices.

Furthermore, as manufacturers adapt to the complexities of the global market, effective quality assurance practices can differentiate companies from their competitors. Utilizing advanced technologies, such as real-time monitoring systems and automated inspection techniques, can enhance production efficiency and accuracy. As the industry's focus shifts towards low-volume, high-complexity production, the commitment to quality must remain steadfast to foster trust with clients and enhance long-term partnerships. By prioritizing quality assurance, companies can secure their position in a rapidly evolving landscape and respond effectively to the needs of diverse global markets.

Comparing Costs: Domestic vs. Chinese CNC Machining Services

When it comes to CNC machining services, cost is a pivotal factor for many businesses, especially when weighing domestic options against those offered by Chinese manufacturers. Domestic CNC machining may present advantages such as shorter lead times and ease of communication due to geographic proximity. However, these benefits often come with a higher price tag. For companies with tight budgets, the premium associated with local machining services can be a deterrent.

In contrast, Chinese CNC machining services often provide significant cost savings that can be attractive for businesses looking to optimize their production expenses. The lower labor costs and scalable manufacturing capabilities in China allow for competitive pricing without sacrificing quality. Many Chinese manufacturers are equipped with advanced technology and adhere to international standards, ensuring that even low-volume production runs can maintain high-quality output. This price differential enables companies to allocate resources elsewhere, advancing their overall business strategy and improving their competitive edge in the global market.

Navigating Challenges and Expectations in CNC Machining Relationships

In the realm of CNC machining, building a trustworthy relationship between providers and global markets has become increasingly crucial, particularly in low-volume production. According to a recent report by Grand View Research, the CNC machining industry is expected to grow at a CAGR of 5.5% from 2021 to 2028, underscoring the rising demand for precision engineering across various sectors. However, navigating the challenges of quality assurance in partnerships with Chinese suppliers necessitates a clear understanding of expectations, communication, and execution.

Cultural differences and time zone disparities can complicate collaboration, but establishing transparent criteria for quality control can mitigate these risks. The Quality Management System (QMS) standard, ISO 9001, has gained traction among Chinese manufacturers, with 90% of companies striving for certification by 2025, according to data from China's National Bureau of Statistics. This trend indicates a commitment to enhancing product reliability and reducing defects, aligning with global market standards. As businesses explore low-volume production, they must emphasize strong communication channels and formal agreements to ensure that those manufacturing expectations are met consistently.